The circular economy in practice: Audi Genuine exchange parts

missing translation: fa.article-intro.reading-time – 10/29/2024

Audi strives to achieve optimal resource savings along the entire value chain and to embed the principle of the circular economy more firmly into the development, production and use of its vehicles. High-quality products that require the least possible repair are aimed at ensuring the longevity of Audi models in their utilization phase and therefore contribute significantly to resource efficiency. Should a part nonetheless need to be exchanged, Audi offers three different exchange options for selected parts:

Brand new parts can be sourced by customers as Audi Genuine parts.

Audi Genuine used parts, on the other hand, are parts that are used but functional and can be resold without remanufacturing.

Audi Genuine exchange parts, in turn, are formerly non-functional, remanufactured Audi Genuine parts. Customers are only given these remanufactured vehicle parts in exchange for a defective part. Ideally, a defective part is exchanged for a remanufactured part. If, for whatever reason, used parts cannot be remanufactured directly within the Audi Genuine exchange parts program, they are replaced by new parts (Audi Genuine parts).

Industrial remanufacturing in line with Audi quality standards

Audi Genuine exchange parts are subject to strict quality controls. Defective components and wearing parts are initially replaced in the remanufacturing process. The remanufactured part is then tested according to defined quality criteria and only approved for re-use if it passes this test. This allows the company to ensure the best possible quality. As with new parts, Audi Genuine exchange parts come with a 24-month warranty.

Industrial remanufacturing of defective parts is a key element of the circular economy. The concept extends the different programs offered by the company to promote the principle of the circular economy along the entire value chain and offers environmental and economic advantages. Remanufacturing allows renewed use of a variety of components within a part and therefore extends the utilization phase of the parts. This in turn saves resources. As a result, Audi Genuine exchange parts are on average 20 percent less expensive than new parts (Audi Genuine parts) and are generally available immediately, meaning no wait times for customers.

Audi Genuine exchange parts are already available in 89 markets. In the past, the range covered remanufactured drive components and electronic parts. Audi recently extended the range to also include remanufactured electric motors and virtual cockpits. Defective catalytic converters and diesel particulate filters can also be exchanged as part of the remanufacturing process. However, they cannot be remanufactured, rather are subsequently recycled and thus returned to the material cycle in this way.

Powertrain remanufacturing enters e-mobility

Audi has decades of experience with the remanufacturing of parts. For more than 70 years, remarkable advances have been made in the remanufacturing of powertrains at the Audi plant in Ingolstadt. This division has already remanufactured more than 7.7 million used powertrains for the Volkswagen Group’s spare parts business, which are also used in other Group brands.

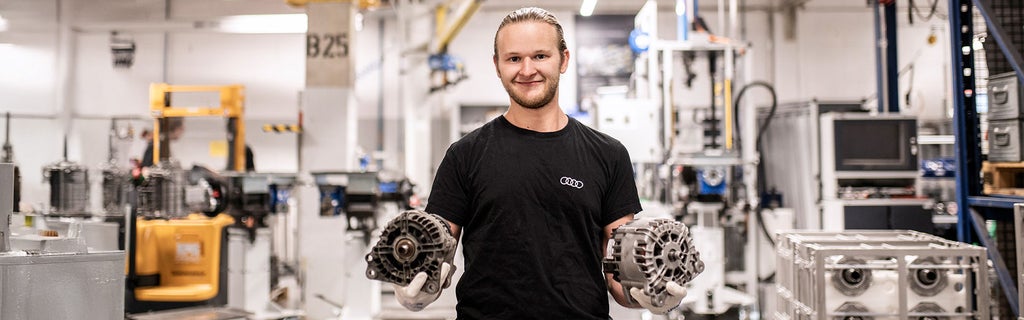

What is new is that aside from remanufacturing generators, starters and mechatronics, Audi also began remanufacturing electric motors in Ingolstadt in 2024. The goal is to remanufacture around 5,000 electric motors annually at the company’s headquarters and then use these again as Audi Genuine exchange parts. Only 2.47 kilograms of new material is needed on average to remanufacture an electric motor, for example to replace seals, screws and bearings with new parts. Essential components such as the housing, the rotor and stator as well as the temperature sensor, on the other hand, can be reused. In comparison, approx. 81 kilograms of material is required for a new electric motor.

In 2023, Audi saved significant quantities of raw materials and components by remanufacturing powertrains at the Ingolstadt site:

tons of steel

tons of copper

tons of aluminum

control units (electronic waste)

electric motors

.jpg)