AI in production at Audi: “A perfect field of application”

missing translation: fa.article-intro.reading-time – 08/05/2021

Stefan Keckl (left) and Rüdiger Eck together with an Audi RS 5 on the production line in Ingolstadt – in accordance with the motto „Vorsprung durch Technik“, Audi is the first automobile manufacturer to apply AI in production.

Stefan Keckl (left) and Rüdiger Eck together with an Audi RS 5 on the production line in Ingolstadt – in accordance with the motto „Vorsprung durch Technik“, Audi is the first automobile manufacturer to apply AI in production.

Rüdiger Eck and Stefan Keckl in conversation

Audi is one of the first car manufacturers to use artificial intelligence (AI) in production. AI experts Rüdiger Eck and Stefan Keckl report how Audi uses the technology and why people will remain indispensable, even in the factory of the future.

Mr. Eck, Keckl, what is artificial intelligence?

Rüdiger Eck: The term “artificial intelligence” makes it sound as though a computer were trying to imitate human intelligence. But in reality, AI today means running a very fast statistical evaluation that makes data-based decisions.

Stefan Keckl: When we train AI algorithms today, a person selects the data and determines what the AI will learn. This lets us transparently show, at any time, how the AI was created.

How great is the potential for AI in automobile production?

Eck: Production is an area where an especially great number of people and machines work on the product together. The interactions between the various steps throughout the process chain are very complex. The process also yields an extremely large amount of high-quality and structured data, which makes production a perfect field of application for AI. AI can simplify and automate processes for all involved, while ensuring product quality and increasing profitability. Today, we assume that digitalization can reduce factory costs by up to 30 percent overall. AI will be a decisive part of that.

Keckl: AI also provides greater transparency around decision-making processes while also controlling them with even greater targeting. We want to improve production day by day, and AI is a perfect tool for that.

Where does Audi already use AI in production today?

Keckl: Audi currently has two specific use cases for artificial intelligence in production. The first is in body construction at the Neckarsulm site, where AI monitors the quality of spot welds. It uses data from the welding machine to conclude whether individual spot welds are in order or not. As a result, Audi employees no longer have to check every single spot weld themselves, focusing instead only on conspicuous ones.

Eck: The other use case is at the Ingolstadt press shop. The AI there checks images of pressed parts to detect cracks. Today, it serves a supportive function by showing the operator a preselection of problematic pieces; in the future, AI will make decisions autonomously. This use case has two advantages. First, the step is automated. And second, the operator benefits from support from AI.

Rüdiger Eck (left) and Stefan Keckl in conversation: they and their team at Audi develop solutions that will enable artificial intelligence to further improve production processes even further.

Today, we assume that digitalization can reduce factory costs by up to 30 percent overall.

Rüdiger Eck

At the Audi press shop in Ingolstadt, AI checks pressed parts for potential cracks. It assists Audi employees in quality control by pre-selecting problematic pieces.

At the Audi press shop in Ingolstadt, AI checks pressed parts for potential cracks. It assists Audi employees in quality control by pre-selecting problematic pieces.

If AI is already automating processes in production today and even works more precisely than humans in some cases, aren’t future scenarios of factory floors devoid of people realistic after all?

Eck: The answer is a clear no. Take assembly work in automotive production for example. This is the least likely area to be replaced by AI. The tasks this entails involve a complex mixture of cognitive performance, physical movement, and sensory perception. Let’s not underestimate that complexity, where humans are clearly better than robots. AI, on the other hand, can take over jobs that humans are not so good at, such as analyzing large amounts of data or repetitive work.

Keckl: In order to excite employees about AI and alleviate concerns like this, it is important above all to explain what AI is and the benefits it brings. If employees don’t have this knowledge, they quickly become defensive because the topic remains so abstract.

In which areas will Audi use AI in production in the future?

Eck: There are four areas in particular where we can fully exploit the potential of AI. First, it can improve product quality by warning when errors occur. Second, it can prevent errors by relieving people of repetitive work that doesn’t add value. Third, AI can optimize processes by revealing correlations that people don’t recognize. This lowers costs by increasing efficiency. And last but not least, AI can frequently help increase the output or performance of processes or machines.

So people and AI will work together?

Eck: We see in AI its potential for assisting people. Just like the different assistance systems in our cars that warn us and help us avoid accidents. We all often make decisions based on gut instinct, but later don’t know whether they are at all correct and sustainable. This is where AI can help us make correct decisions and recognize mistakes after the fact. People will always make mistakes, but AI will let us notice them immediately in the future.

Keckl: We are already working on solutions so that end users can build small AI solutions themselves. We also want to enable employees to organize as a team on their own. They can rely on AI to detect any errors that occur so they can concentrate on their actual work. That’s when AI is really fun because it allows the people in the system to be independent.

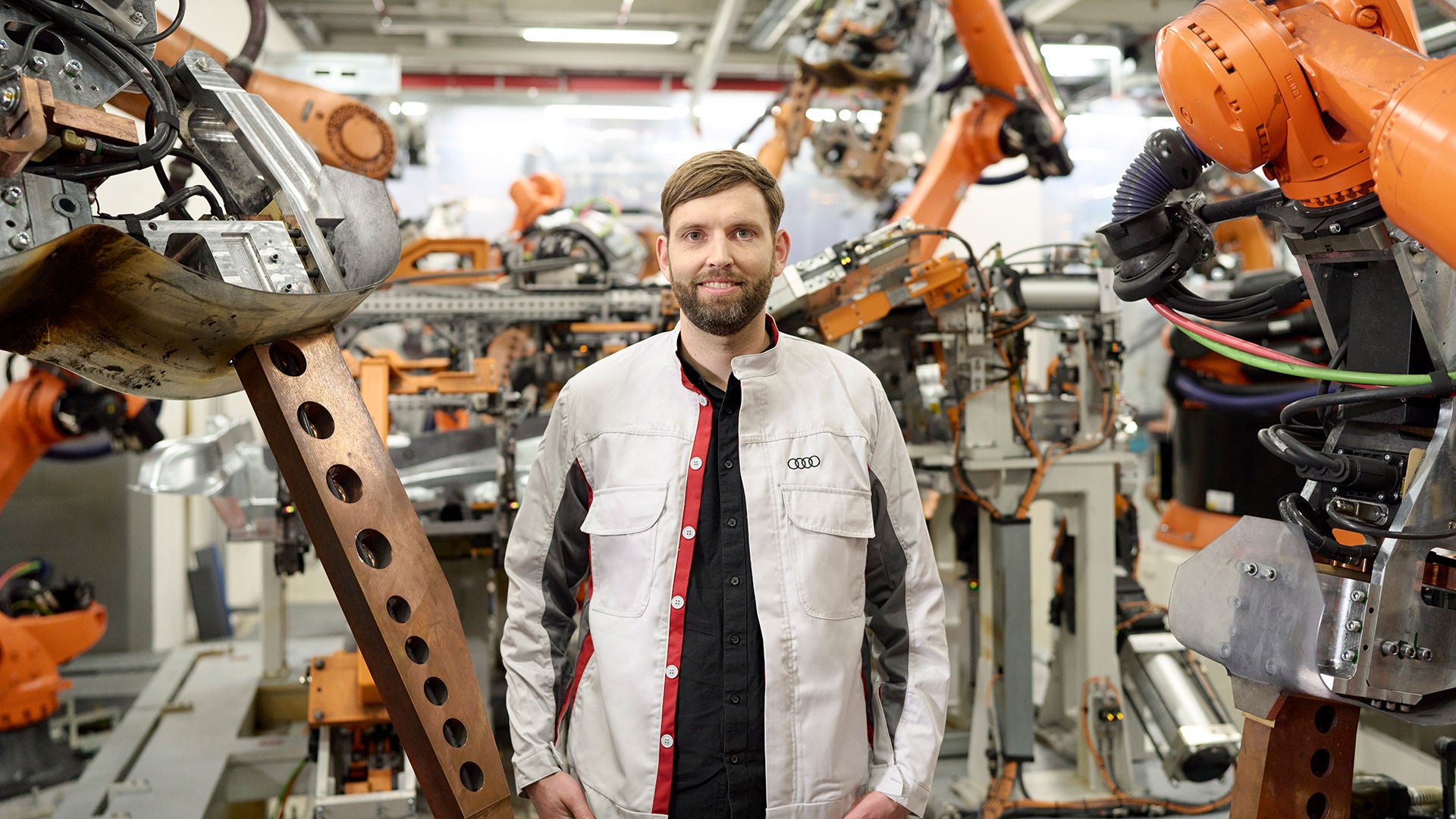

AI-Experts Stefan Keckl (left) and Rüdiger Eck explain how Audi utilizes AI in production and why humans will remain indispensable in the factory of the future.

We need to and want to become a data-driven company.

Rüdiger Eck

How many people are working at Audi on AI in production?

Eck: Right now, some 60 data-savvy people at Audi are working on how we can leverage AI within our production processes. About a dozen of them are working on machine learning and data science.

Keckl: There are also a lot of people who’ve switched into the team who bring a lot of passion and knowledge of production processes. They are continuing their training in AI, and it works really well.

Eck: We are currently the ones developing AI systems for production. But in order for AI to reach its full potential, we need to embrace making data-based decisions on a company-wide scale. We need to and want to become a data-driven company.