The vehicle referred to is a concept car that is not available in series production.

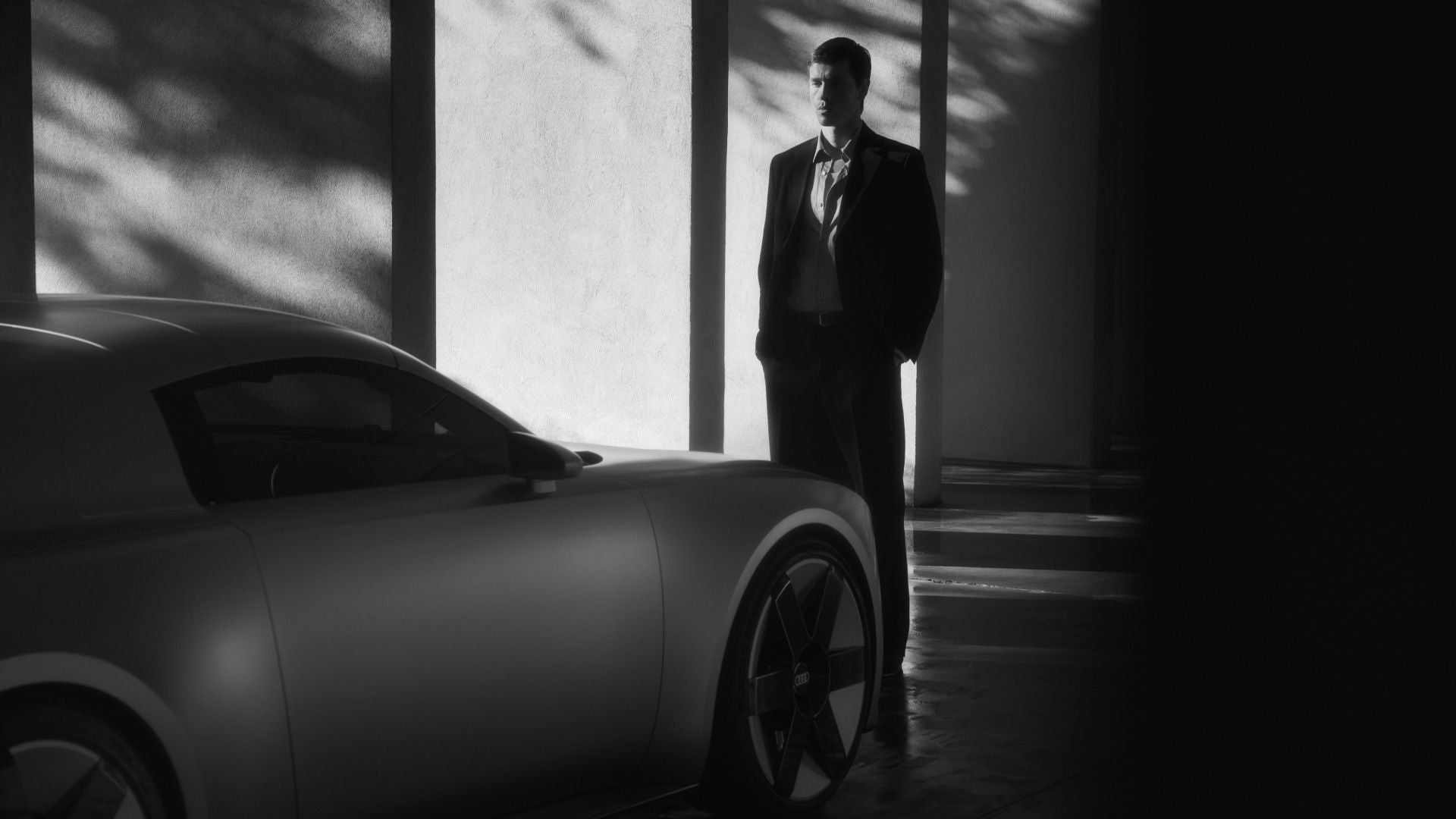

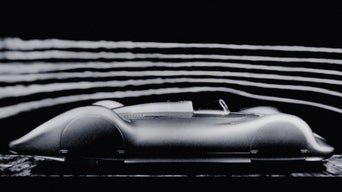

Design

Audi design philosophy is based on four principles: clear, technical, intelligent and emotional.

Focusing its design on the essential, the brand stands for a reduced and timeless aesthetic. This approach extends to every aspect of the car – and beyond.