Major steps toward an electric future

missing translation: fa.article-intro.reading-time – 01/23/2024

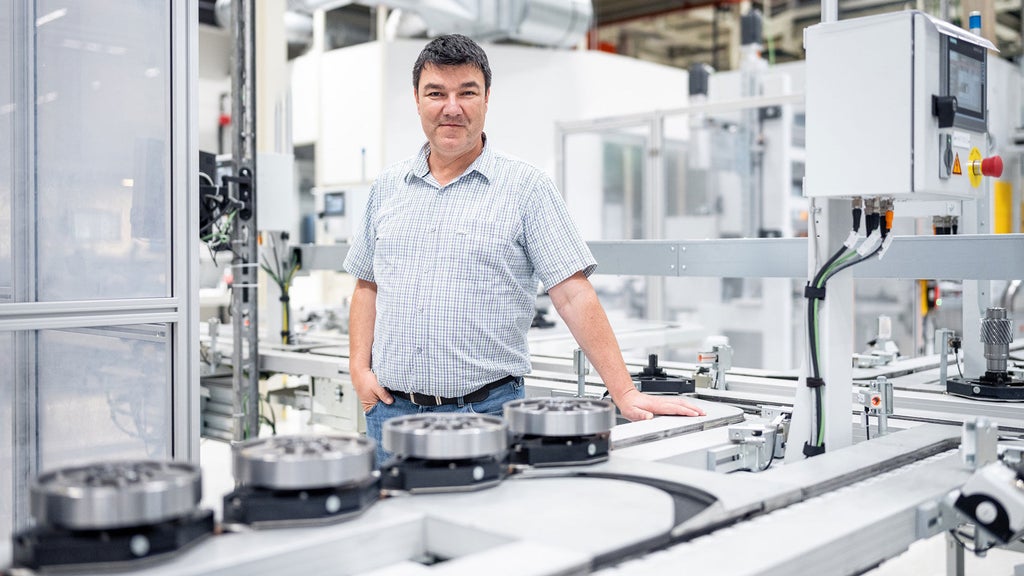

Attila Kovacs plans drives for the Premium Platform Electric (PPE), which the new Audi Q6 e-tron is based on.

Attila Kovacs plans drives for the Premium Platform Electric (PPE), which the new Audi Q6 e-tron is based on.

A few years ago, a car mechanic whispered a saying to the Hungarian engineer Attila Kovacs: “If you run in place, you wear out your shoes. If you courageously move forward, you’ll achieve something.” Kovacs always liked wise sayings like this, and he took it to heart. The mechanical engineer has worked for Audi Hungaria in Győr for 25 years. Now, after taking up the challenge and switching from combustion engines to electric drives within the Production Planning department in 2019, he ranks among the company’s experts in electromobility.

“This technology will play a leading role in the future,” he said. “I want to do my part to that end.” It was a decision that had been maturing for a few years. “It was like a mosquito in my ear that I could constantly hear.” His supervisor encouraged him in his decision – and the Audi Academy helped fill in missing knowledge with its training program for engineers.

Developing targeted new skills

To advance the transition to electromobility, the four rings need new skills. For the ramp-up of the Audi Q6 e-tron range in Ingolstadt, for instance, Audi has thus far qualified 8,300 employees from the Production, Technical Development and Sales divisions. This was done through measures combining theory and practice, individually tailored to the employees. At the same time, Audi has hired 500 new colleagues to manufacture the Audi Q6 e-tron in Ingolstadt’s production facilities.

Drive train planning for the new vehicle platform

Since 2022, around 2,000 employees have also completed further training for electrification at Audi Hungaria in Győr, where the electric drives for the car are manufactured – employees like Attila Kovacs, who has no regrets about his change. Since 2021, he and his team have been planning the drives for the new Premium Platform Electric (PPE), which the new Audi Q6 e-tron is based on. “I’m proud to contribute to this important technology,” Kovacs said. “Reinventing yourself every now and then freshens the mind and renews motivation.”

Maria Salbeck transfers to new battery assembly

Around 600 kilometers to the west, at the Audi headquarters in Ingolstadt, Maria Salbeck also decided to switch to electromobility. The mechatronics technician in automation technology trained to become an expert in battery assembly in Ingolstadt. Before that, she worked as a plant operator in the paint shop, most recently as a co-trainer at the Audi Training Center. “Then I wanted to get back into production, back to the product,” Salbeck said. Now she’s responsible for a wide range of technologies in battery assembly, and she supervises an entire assembly line section. “Sometimes you have to take a more difficult path and trust yourself to dive in at the deep end.”

Moving forward with a pioneering spirit

High-voltage battery planning in Ingolstadt also relies on courageous employees like Maria Salbeck and Attila Kovacs. After all, trained battery planners can’t be found in the labor market. As a result, the approximately 60 employees for high-voltage battery planning were found in other departments and trained internally. They originally came from tool and plant construction, logistics, battery development and production. It's a motley crew – from young technicians to experienced assembly planners, with backgrounds ranging from theoretical to practical, from Győr, Brussels or Ingolstadt.

Sebastian Frei, Head of High-Voltage Battery Planning, is proud of his team. “We combine the best of all worlds,” he said. What unites them all is a pioneering spirit. The qualification program for his employees is based on several pillars that are tailored to respective levels of knowledge. For instance, those who come from a planning background have to learn high-voltage technology, while others start from scratch with the basics of planning. In addition to completing internal training courses from the Audi Academy, every newcomer is supported by an experienced specialist in the beginning thanks to a mentor model.

“We’re investing in the future here

Sebastian Frei

The high-voltage battery planning team is currently working on the Audi Q6 e-tron, which will soon be introduced to the global public for the first time at the Annual Press Conference in March. And more projects will soon follow, including the establishment of battery production facilities at other locations. Knowledge is being exchanged throughout the Group and in both directions. For instance, Frei visited Škoda in Mladá Boleslav to check out the battery planning there and work on solutions together. “The Audi Q6 e-tron will remain in my memory for a long time as a special, innovative project. At the same time, things are moving on – there’s always something new to develop. We’re investing in the future here,” Frei said. In his opinion, battery planning is “one of the most attractive jobs at Audi.”

“The Audi Q6 e-tron will remain in my memory for a long time as a special, innovative project.

Sebastian Frei

In summary, in building up new skills, Audi is paving the way to a future in which the four rings will gradually phase out the production of cars with combustion engines worldwide by 2033. Until then, the last generation of combustion-powered cars with state-of-the-art engines will continue to contribute to the company’s success. Experts in combustion technology are consequently still urgently needed to lay the foundation for investments in electromobility. Of course, it can’t be ruled out that they too will reinvent themselves in the future.